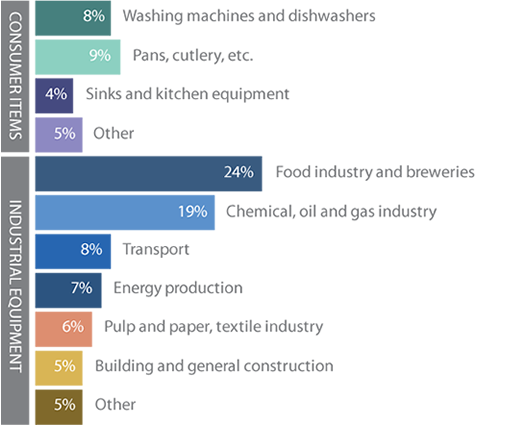

Most Common Applications Seen in Our Products

Cold Heading Wire (application samples 1/4)

Cold heading wire is mostly used in the manufacturing of bolts, nuts, rivets, and other types of fasteners. The above picture shows our customers' end products.

Cold Heading Wire (application samples 2/4)

Specially made cold heading wire is ductile enough to form special fastener's complex shapes and yet strong enough to perform when put in use.

Cold Heading Wire (application samples 3/4)

Special and customized cold heading wire are used in the most difficult applications of complex components. Picture above shows our customers' products.

Cold Heading Wire (application samples 4/4)

The mechanical properties of cold heading wire require a careful balanced chemical compositions. We provide the perticular kind of wire for the processing.

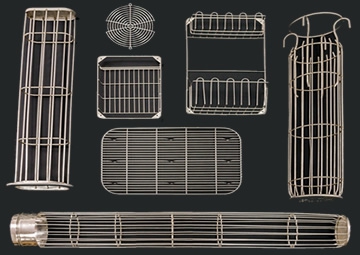

EPQ Wire (Electro Polishing Quality)

EPQ Wire is used for fabricated baskets, racks and trolleys. This wire has special surface characteristics that result in a very lustrous appearance.

Spoke Wire

Spoke wire combines high hardness with good tensile strength to create excellent impact resistance, therefore, spoke wire is commonly used for bicycle and motorcycle tires.

Mesh Wire

Mesh/weaving wire has various tensile strengths that the finished screen has adequate strength to withstand service loads and yet soft enough to be formed.

Redraw Wire

Redraw wire is mainly used in the weaving of fabrics, and for further drawing into fine and super fine wires. Has the characteristic of extremely clean surface.

Nail Wire

Nail wire with superior corrosion resistance is used for making coil gun nails and collated strip nails in industrial, construction and marine fields.