Supplying the Best Precision Drawn Wires

.Wire drawing is often referred to cold drawing, it is a process of reducing the cross section of a wire by pulling through a die or series of dies. Because of the increasing demands of wire properties, demands of wire drawing machines are also on the rise.

To supply the best precision drawn wires to our customers, TY Metal constantly upgrades machines of its drawing machinery in order to manufacture the highest level quality wires.

Our drawing machines including:

- Series 600 vertical drawing machine for precision wire drawing

- Series 800 vertical drawing machine for up to 10 mm wire drawing

- Series 1300 vertical drawing machine for 9 mm-25 mm wire drawing

- German 8-block straight-lined drawing machine for 1.6 mm-and-up wire drawing

- German 9-block straight-lined drawing machine for 0.7 mm-and-up wire drawing

- Taiwanese Series 400 8-block drawing machine for 1.0 mm-and-up wire drawing

- Taiwanese Series 600 8-block drawing machine for 1.6 mm-and-up wire drawing

- Multi-speed inverted vertical drawing machine

Taiwanese 8-block straight-lined drawing machine

Taiwanese 8-block straight-lined drawing machine German 8-block straight-lined drawing machine

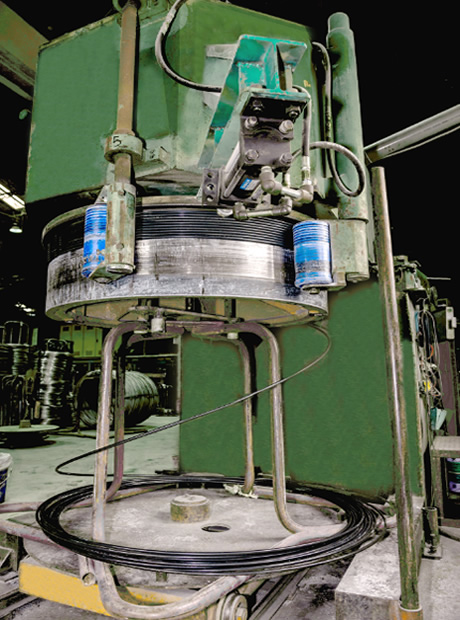

German 8-block straight-lined drawing machine Series 800 vertical drawing machine

Series 800 vertical drawing machine Series 1300 vertical drawing machine

Series 1300 vertical drawing machine