Our wires are directly usable as manufacturing materials for our customers. End use of our customers' applications can be seen everywhere.

TY Metal specializes in processing raw wire rods to annealed, tempered and hard wires for manufacturers in many industries. Our decades of experience has established a sound reputation in the wire processing sector.

We offer various application solutions for customers, whether they are in construction, automobile or aerospace industries. Our materials are ready to be used as the supplying material for our manufacturing customers.

Below are examples of end-use applications that utilise TY Metal's manufactured products.

TY Metal produces special wires for a variety of applications, each has respective exacting specifications. We employ the most experienced engineers to design solutions for our customers' applications.

With our state-of-art machinery and facility, we give our customers unparalleled support and global reach. We partner up with customers to deliver quality end-use products. If you have technical or general questions, contact us or just drop a note.

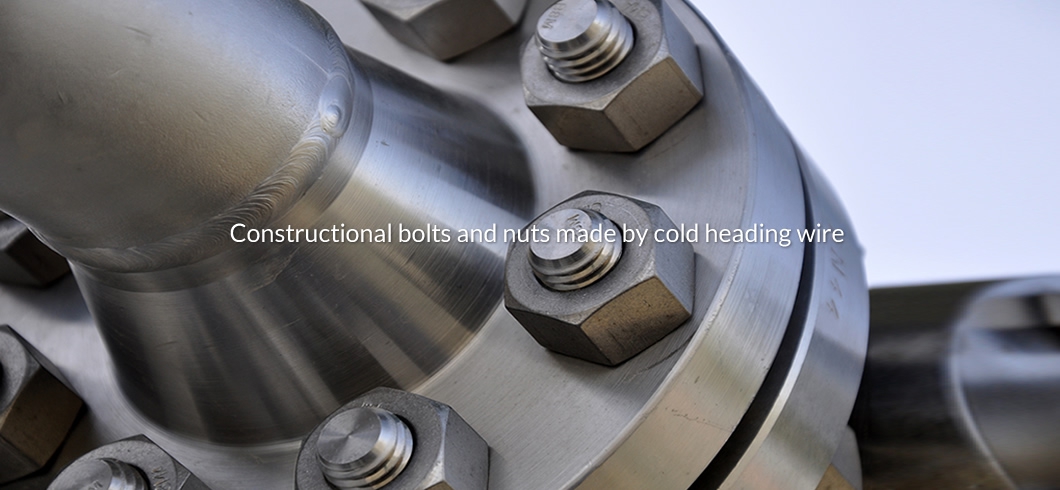

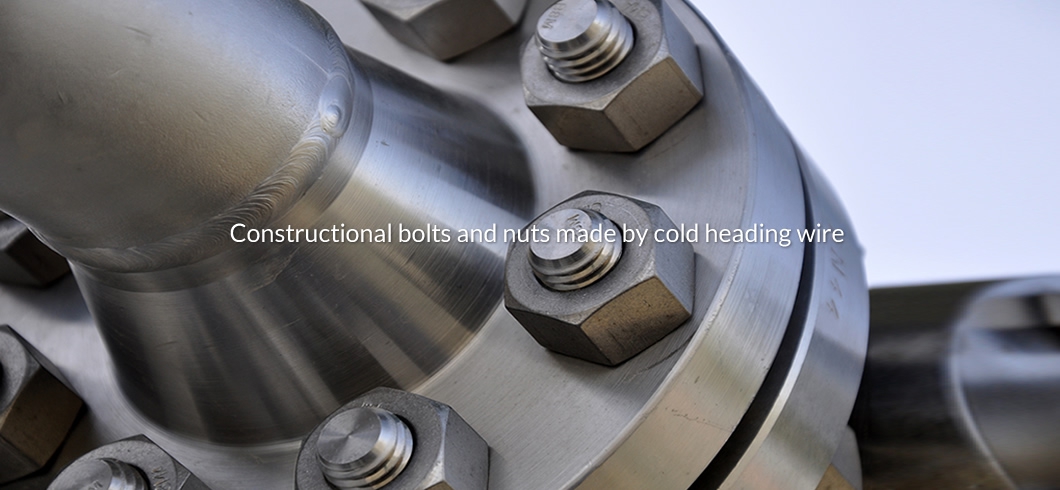

Cold Heading Wire |

Bolts, nuts, screws, rivets for automotive, aviation, construction and household items. |

EPQ Wire |

Baskets, racks, kitchenware, trolleys and cable trays; filter cages used in filtration for dust collection. |

Spoke Wire |

Spokes for motorbikes, bicycles, car wheels and umbrellas. |

Mesh Wire |

Wire mesh, welded wire mesh and conveyor belts. |

Redraw Wire |

Electrodes, wire ropes, staples, chains and dental braces. |

Nail Wire |

Collated siding nails, coil gun nails, pallet nails, framing nails, furniture staples, brad nails and fence nails. |

Stainless steel products need to be cleaned to keep up an unstained appearance and to preserve corrosion resistance. They do not remain stainless at all times. Corrosive substances would accumulate if lacked of cleaning, and they'd surpass the corrosion resistance of the steel grade selected.

Advise: clean the stainless steel surface when it's dirty to maintain the pristine appearance. The frequency varies from one to four times per year for industrial applications, to once a day for hygienic items.