- Remove surface blemishes

- Improve the wire shape

- Achieve the desired mechanical properties

Products

Application

Capability

About TYMI

Search

Please enter the unit title or item title, along with a brief description, that you wish to search for.

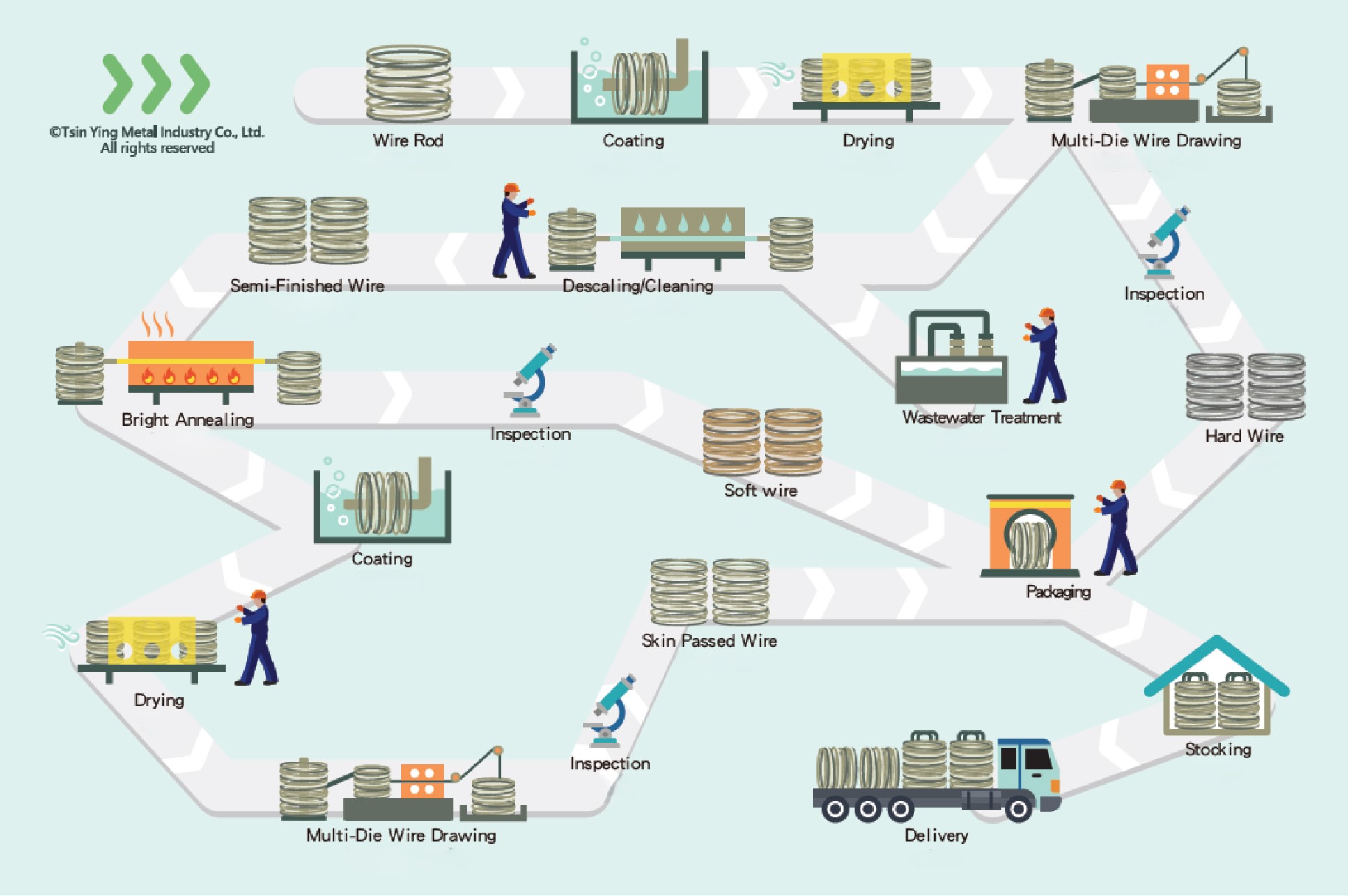

Main Steps of Work Process

Our Well-Thought-Through Work Process

An overview of TY Metal processing line:

•Once the wire rod delivered to our facility, it's bathed into a coating tank and then baked in preparation for the drawing process

• When the coated wire rod dried, it'd be put through a series of multi-die wire drawing machines to reduce the diameter till desired

• The wire can also be annealed to soften it by fed through a furnace where it is heated then quenched in water

• It may then be drawn again to the exact diameter required by the customer

Cold Drawing Line

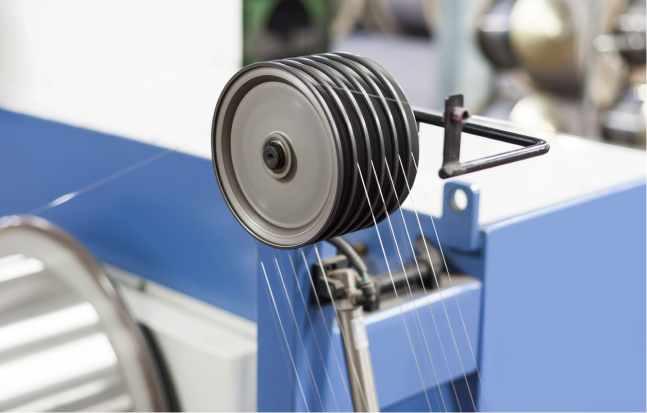

Wire Drawing Is An Significant Step In Manufacturing Processed Wires.

Wire drawing is often referred to cold drawing, it is a process of reducing the cross section of a wire by pulling through a die or series of dies. Because of the increasing demands of wire properties, demands of wire drawing machines are also on the rise.

Our Drawing Machines

To supply the best precision drawn wires to our customers, TY Metal constantly upgrades machines of its drawing machinery in order to manufacture the highest level quality wires.

Our drawing machines including:

- Wire Drawing Machine with Annealing

- Continuous Wire Drawing Machine

- One-Pass Wire Drawing Machine

Wire Drawing Range & Tolerance

The range of our wires are (* Please inquire for sizes outside of this range) :

- Hard Wire: 3.0 to 25.0mm

- Annealed Wire: 0.8 to 10.0mm

- Skinpassed Wire: 0.8 to 25.0mm

| Description | Diameter | Standard tolerance | |

|---|---|---|---|

| Annealed Skinpassed Wire | 0.8 mm - 10.0 mm | ± 0.02 mm | |

| over 10.0 mm | ± 0.04 mm | ||

| Hard wire | 3.0 mm - 25.0 mm | ± 0.05 mm |

Annealing Line

TY Metal's Furnaces Process Wires In High Speed. Annealed To Achieve Optimum Results

TY Metal's annealing line includes three furnaces, they are state-of-the-art and process wires in high speed. These continuous wire annealing furnaces are essential in our production workflow, they eliminate the lubricants on the wire and anneal the stainless steel wire to certain tensile strength.

The temperature and power of our furnaces can be completely controlled. To reduce atmosphere, the furnaces are equipped with gas manifolds to allow respective control of each process. TY Metal's furnaces are also furnished with water-cooling tanks to facilitate temperature control and they require minimal maintenance.

Below is a glance of our continuous wire annealing furnaces.

Zoned For The Best Performance

Our wire annealing furnace is heated in multiple zones to fast heat-transfer to the wires and perform consistant temperature. The fume extraction system and covers are set up to increase safety and reduce environmental impact. Each of our continuous annealing furnace includes 3 parts:

- the combustion chamber, heated by 1 to 3 burners

- the waste gases that are guided into the entrance of furnace

- against the heat current, wires going through the furnace

Because our furnaces are equipped with a wide range control of temperature and speeds, we can obtain different wire tensile strengths. Wires that do not have to be annealed can also be passed through the foundations of the furnace. Wires we processed can go down to 0.8mm diameter with various tensile strengths acheived.

Efficiently Operated Furnaces

In order to obtain the best annealed wires with consistent and precise tensile strength, TY Metal is established with the state-of-the-art furnaces. Features of our bright annealing furnaces are:

- High wire speeds

- Low operation cost and low consumption

- State-of-the-art combustion & control

- Solidly built for long-standing production

- Channels are individually adjustable

- Easy operation — combustion chamber heated by only 1 to 3 burners

- Approx. 40 to 90kg/mm² tensile strengths can be achieved

- The entire heating cover can be lifted for combustion chamber maintenance

Precision Wire Drawing

We Are Capable Of Drawing Wire Down To Diameters Between 0.8mm And 25mm

The minimum diameter of wire rod supplied to TY Metal is 5.5mm, and we are capable of drawing wire down to diameters between 0.8mm and 25mm.

Exceptional wire drawing capbilities and knowledge

Our production facilities and technical staff have exceptional wire drawing capbilities and knowledge from product specifications to flexible packaging. With decades of experience of manufacturing wire products, TY Metal has established a holistic knowledge of wire processing and material specifications.

The quality of the product is determined by the wire drawing production process

Different grades of steel can be formed into various properties with different processing. The production process affects the quality of the wires and application products.

Attentively care for each step

We draw down wire rods until final product meets the buyer's requests for diameter, mechanical properties and surface finish. We attentively care for each step during the production.

Stages of Our Wire Drawing Process

Cleaning

Remove abrasive scale on the surface of raw wire rods.

Coating

Apply drawing lubricant onto the surface of the wire to aid cold drawing.

Pointing

Because the dies are always smaller than the section of wire, we sharpen the wire ends so it can pass through the drawing dies smoothly.

Drawing

The pointed end of the wire passes through the dies and enters a gripping device of the drawing machine. The drawing machine pulls the remaining of the wire to go through the dies. The wire's cross section is reduced and its profile shaped.

Finished Wire

The drawn products appeared a bright finish, with desired mechanical properties.

Multi-Pass Drawing

To produce the desired shape and tolerances for complex wire profiles, coils may need to be drawn several times. This process let wires draw through smaller and smaller die openings. To increase ductility and remove cold work, wires are usually annealed between each drawing pass.

privacy policy

Welcome to the "TY Metal Website" (hereinafter referred to as "this website"). To ensure that you can use the services and information on this website with peace of mind, we hereby explain the privacy protection policy to safeguard your rights. Please read the following content carefully:

Scope of Application for Privacy Protection Policy

The privacy protection policy covers how this website handles personal identification data collected when you use the services of this website. The privacy protection policy does not apply to related linked websites outside of this website, nor does it apply to personnel not commissioned or involved in the management of this website.

Collection, Processing, and Use of Personal Data

When you visit this website or use the functional services provided by this website, we will ask you to provide the necessary personal information depending on the service function, and we will process and use your personal data within the specific purpose. Without your written consent, this website will not use your personal data for other purposes.

When you use interactive functions such as service mailboxes or surveys on this website, we will retain the name, email address, contact information, and usage time you provide. During general browsing, the server will automatically record relevant actions, including the IP address of your connecting device, the time of use, the browser used, and the browsing and clicking data records, as a reference for improving our website services. This record is for internal use only and will never be published externally.

To provide precise services, we will conduct statistical analysis on the content collected from surveys. The statistical data or explanatory text of the analysis results will be presented internally. We may publish statistical data and explanatory text when necessary, but it will not involve data on specific individuals.

Data Protection

The host servers of this website are equipped with firewalls, antivirus systems, and other related information security equipment and necessary security protection measures to protect the website and your personal data with strict protection measures. Only authorized personnel can access your personal data, and relevant handling personnel have signed confidentiality contracts. Anyone who violates the confidentiality obligation will be subject to relevant legal action.

If it is necessary to commission other units to provide services due to business needs, this website will also strictly require them to comply with confidentiality obligations and take necessary inspection procedures to ensure they comply.

Relevant Links to External Websites

The web pages of this website provide links to other websites. You can also access other websites through the links provided on this website. However, the privacy protection policy of this website does not apply to those linked websites. You must refer to the privacy protection policy of those linked websites.

Policy on Sharing Personal Data with Third Parties

This website will never provide, exchange, rent, or sell any of your personal data to other individuals, groups, private enterprises, or public agencies, except in cases where there is a legal basis or contractual obligation.

Use of Cookies

To provide you with the best service, this website will place and access our Cookies on your computer. If you do not wish to accept the writing of Cookies, you can set the privacy level in the browser function items you use to a higher level to refuse the writing of Cookies. However, this may cause some functions of the website to be unable to perform properly.

Amendments to the Privacy Protection Policy

The privacy protection policy of this website will be amended as needed and will be published on the website after the amendment.

Limitation Of Liability

The information contained in the tymi.com.tw is not intended to be an exhaustive statement of all relevant data applicable to special and general steel wire products. It has been designed as a guide for customers to the wire products TY Metal can offer. No responsibility is implied or accepted for or in connection with quality or standard of any product on its suitability for any purpose or use.

It is the responsibility of the user to ensure product specified is fit for the purpose intended. In no event shall TY Metal be liable for any indirect, incidental, special, punitive or consequential loss, damage or expense of any nature. TY Metal's maximum liability for any claim, loss or damage shall not exceed the purchase price under any circumstance, even if end-user has claims or is subject to claims in excess of this limitation.